A Perspective Look at Pipeline Skids vs Construction Mats

Pipeline projects require dependable ground support, but not all solutions are created equal. Contractors often weigh pipeline skids against construction-grade composite mats when deciding how to stabilize terrain, protect equipment, and meet environmental requirements. Each option brings unique advantages and limitations, and understanding the differences can help you avoid costly missteps in the field.

Performance Under Load

Pipeline skids, usually timber, elevate pipe and allow airflow. They work for short-term stabilization but can degrade quickly with moisture and repeated handling. Construction mats spread loads evenly and stay consistent on wet or uneven ground, making them better for repeated heavy-equipment traffic and haul roads.

Environmental Impact

Because pipeline skids are wood-based, they can rot, absorb chemicals, or carry invasive species from one site to another. Construction mats offer a more controlled profile. Composite mats, in particular, resist absorption and are easier to clean, reducing cross-contamination risks. This difference becomes critical in sensitive areas such as wetlands or agricultural land.

Composite HDPE interlocking mats — best for wetlands corridors, agricultural fields, and soft rights-of-way where fast cleanup and decontamination are required under permits.

Timber/hardwood crane mats — suitable for short-duration, static lifts on firmer upland areas where cost sensitivity outweighs long-term reuse.

Trackout/egress mats — positioned at site exits to reduce sediment transfer, plant material, and contaminants from tracked or wheeled equipment entering public roads.

Cost and Longevity

Upfront, skids are cheaper. But frequent replacement and disposal add up fast. Composite mats typically deliver more service life and can be redeployed across projects, lowering effective cost per use.

Handling and Logistics

Skids are heavy and require more equipment to move, stack, and reposition. Interlocking construction mats are lighter and faster to install, which matters when access must be built and removed multiple times or when weather windows are tight.

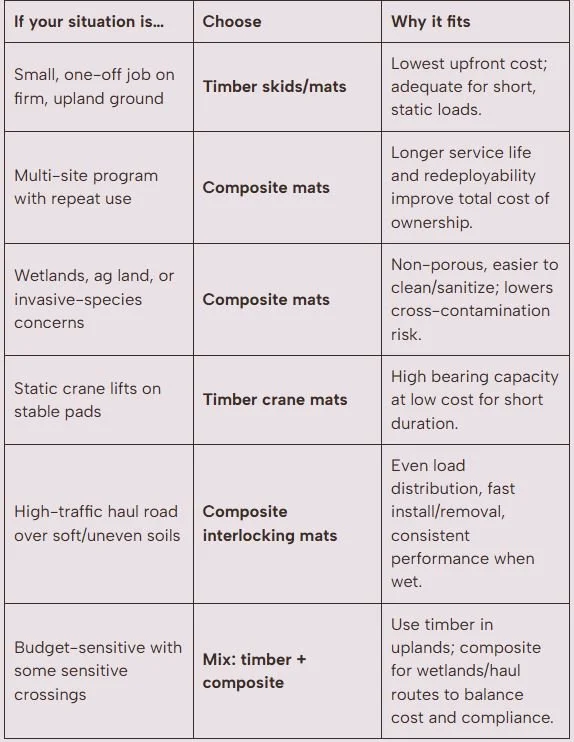

Key comparison points

Use this at-a-glance summary as a scoping checklist. Confirm each point against soil conditions, load cases, handling needs, and lifecycle budget before procurement.

Timber skids/mats: lower upfront cost, shorter lifespan, heavier to handle

Composite mats: higher initial cost, longer lifespan, lighter and easier to clean

Use-fit: composites lower environmental risk; timber can fit short, static-load projects

Maintenance & cleanliness: composites are non-porous/easier to sanitize; timber can retain moisture and oils

Which Mat To Use

For temporary elevation alone, skids can be enough. For reliable access, repeat use, and simpler cleanup, construction mats offer better lifecycle value. Explore specifications or request a quote to find out what construction mats can do for you.